Modern Supply Chain Demands

The 3 Ts of Supply Chain Demand: Transactions, Transparency, and Transformation

The traceability of goods from the factory to the point of sales, and even to the consumers, is crucial for the consumer goods industry. It enables companies in the food industry to monitor their shipments and thereby increases both the safety of their products and the level of trust among consumers.

In recent years, countries and large economies such as EU, China, US, and Russia have issued comprehensive traceability rules and regulations for the food industry. For products that are more susceptible to fraud, i.e. baby food and alcohol, a unique code on the package is mandatory to trace them back to their producers. The objective is to effectively prevent counterfeits and diversions, and to ensure an effective recall, less costly process for supply chain management.

“According to Food Safety Magazine, 337 US food products have been recalled in 2019 due to various quality issues.”

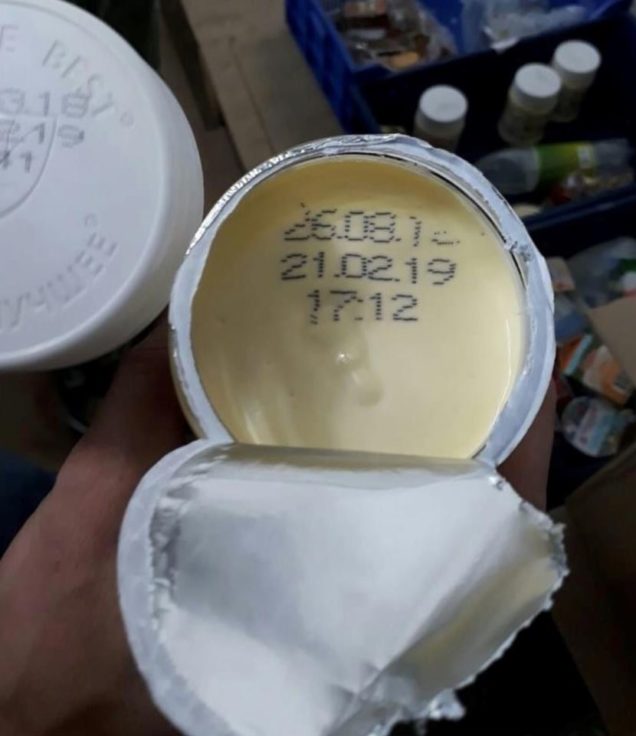

positioning of print!?

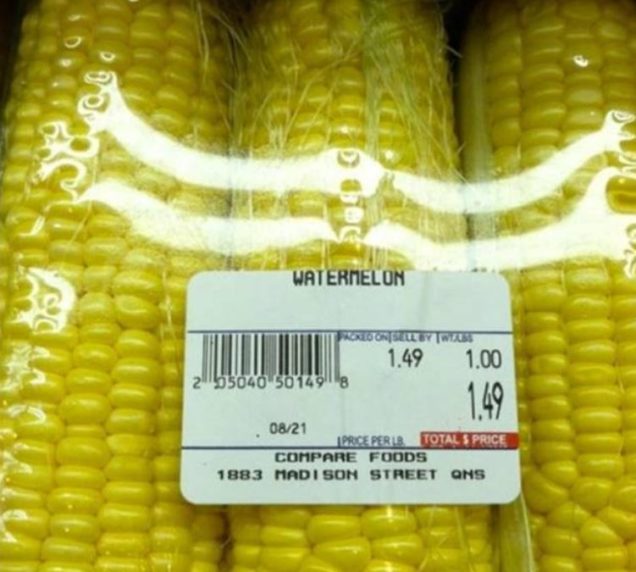

watermelon or corn?

Defective products not only raise your operating costs due to the penalties issued by retailers, but also damage your brand’s reputation. To save logistics expenses and avoid shipping faulty products to retailers’ warehouses, errors and defects should be detected at the production plants and reject right on the packaging lines.

For a robust supply chain process, you need this 3T approach:

Log every TRANSACTION

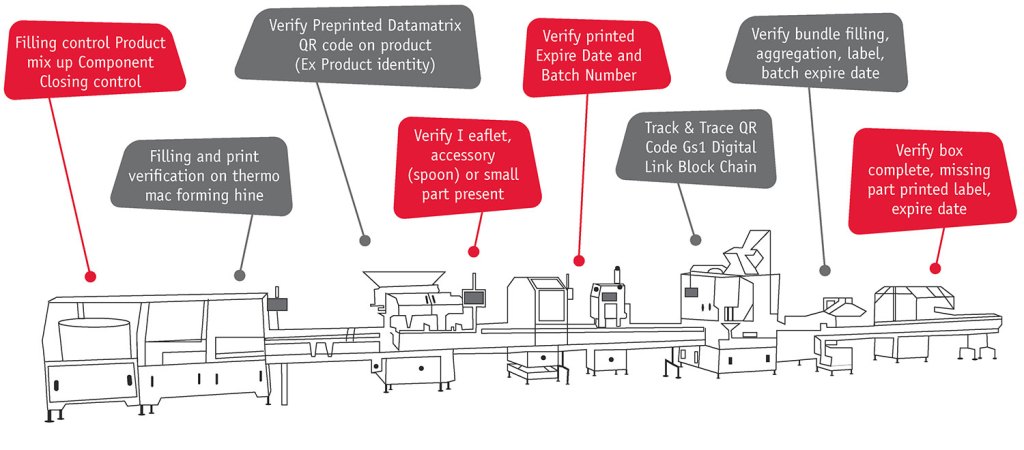

There is variety of processes defined for manufacturing and shipping food products. Using predetermined criteria on the food production line, cameras will inspect and detect defects related to product and packaging in real time. The camera is driven by software that record defects. The software on the production line is interfacing with your ERP system, which contains and transmits a consistent data stream to enable the manufacturing processes to be controlled, evaluated and optimized.

Depending on the food product and quality requirements, several packaging inspections should be placed on your production line to ensure the desired quality of finishing goods. Hardware solutions such as color cameras, code readers, scanners and sensors which are used to inspect different features:

- Orientation: verify that a code, such as batch number, production lot, expiration date are aligned correctly.

- Print quality: check if the quality of the code is readable, straight, and with the appropriate contrast.

- 1D/2D coding: bar codes and 2D codes are utilized for marking and identification of products. During inspection, the codes are read by a camera and compared with a reference code stored in the software system. If the code is not readable or if it does not exist in the database, the system reports an error message.

- Color: color inspection is used to check color on individual items that will be put into the package. It enables you to differentiate primary items from foreign elements (such as nails or insects) that would cause contamination.

With code inspection of every product, the software system will link goods from the production line to their packaging carton. This technology will minimize default products and lower your operating costs.

Ensure TRANSPARENCY across functions and departments

Supply chain risk management is a tremendous challenge for operation, distribution, and logistic managers. Some economies such as the EU and the US already implemented traceability regulations to protect public health and enhance food safety. According to these regulations, companies must be able to trace goods back to their batch level in case of a recall. Globalization increases the complexity of supply chain management. According to McKinsey’s survey2 of 639 executives in various countries and industries, 72% expected the risk of supply chain disruption to continue to rise.

The supply chain function remains right at the center of companies’ organizational structure – after manufacturing, before sales and customer service. A sturdy and effective process to ship the right product to the right place requires close collaborations across job functions and departments within a company. A continuous data flow and transparency of information flow are the foundation for a strong communication and collaboration of all stakeholders.

Digitizing supply chain management is not only about technologies, the most important and difficult part to change is the organization. Transparency provides a shared vision and a common goal for each stakeholder to pursue: the customer at the center of the value chain. With this in mind, each decision is focused on building a positive experience and a tighter relationship with your customers.

TRANSFORM supply chain data and procedures

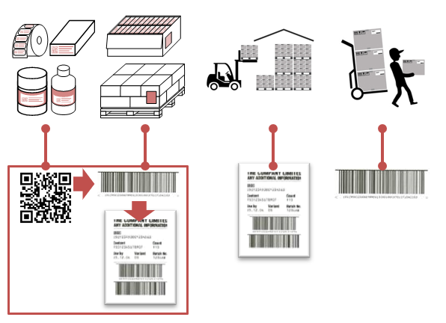

Enabling transparent traceability involves aggregation and de-aggregation of data. By having a unique code printed on the individual product, your system knows which can of infant formula is shipped in which carton, and transferred to which container, then loaded in which fleet, and finally arrives at which retail shop. During these tracking procedures, massive data analysis is performed in the back-end, while in the front-end, data is simply gathered by scanning the bar code or the QR code.

This technology has been widely implemented in the pharmaceutical industry due to regulation requirements. Since 2018, food giants have also pivoted toward track and trace projects. In 2017, Nestlé initiated a 3-year global program for suppliers and supply chain traceability3. In 2020, Danone launched Track & Connect service to protect their most vulnerable consumers: the babies4. Retailers are also start looking out for track and trace solutions, e.g. Walmart requires more and more food suppliers to use traceability systems to track the origin of their products5.

To implement the hardware on a production line and the software to capture data are challenging. That is what we are here for. Laetus has been a specialist in track and trace solutions for more than 45 years and has helped many companies to ensure product safety and traceability. Thanks to the modular solutions, our systems can be easily adapted to the specific needs of your production environment. This scalability also ensures an optimum price-performance ratio for you. We are your business partner with a shared vision of digitalization and supply chain traceability. We offer solutions for your food packaging line that address every stage of your supply chain transformation plan.