Quality Control Solutions

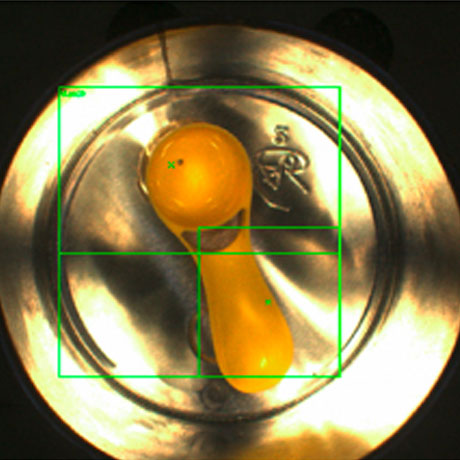

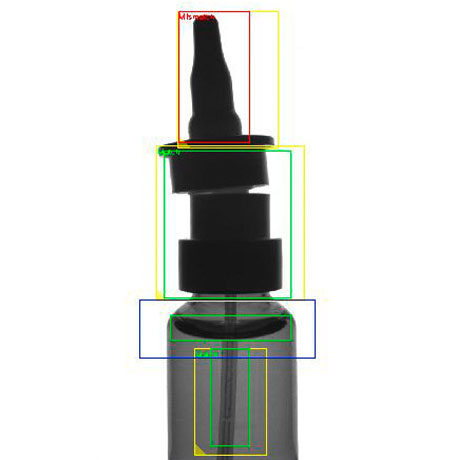

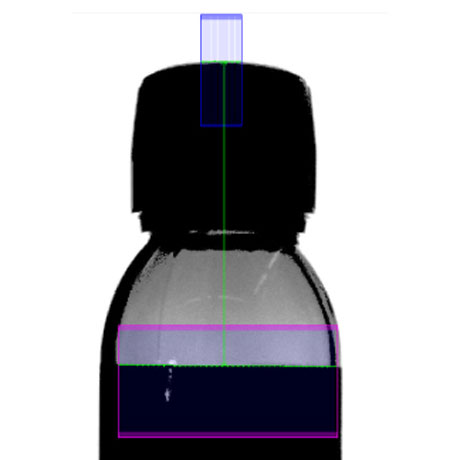

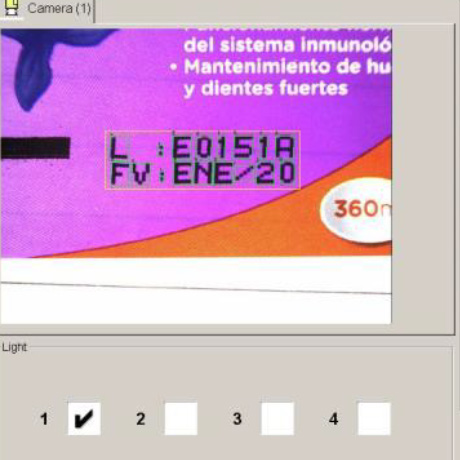

Vision Inspection and Quality Control solutions are an essential part of a track & trace solution. Integrated on Track & Trace machines they can provide: presence monitoring for completeness of all packaging contents, ampule color ring identification, fill level control of bottles, blister fill control, inspection of the print quality of codes and design features, reading and recording of expiration dates, product codes and batch designations.

Item Quality Control System

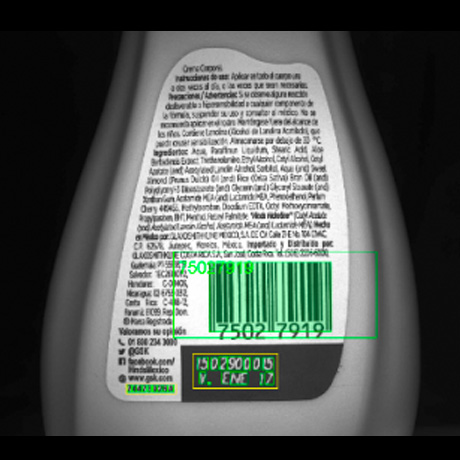

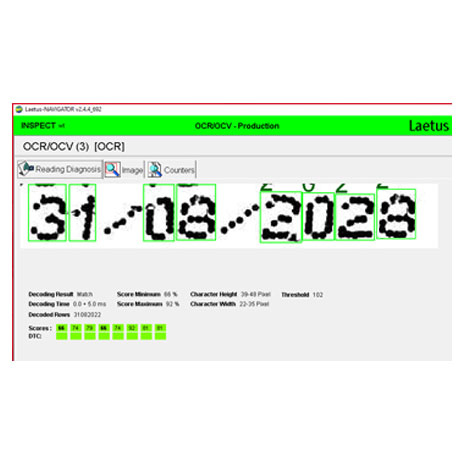

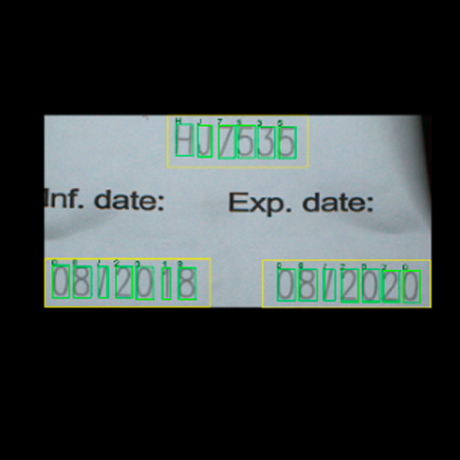

The packaging for individual products displays a broad range of important information and artwork, from human readable alphanumeric – including expiration dates, serial numbers and product names – to machine-readable data, such as barcodes or data matrix codes. Much of this is essential to the end user as it confirms product authenticity and provides the key information that the customer needs to know, helping them to trust the brand and avoid any potential misuse or health issues.

Product Identification Solutions

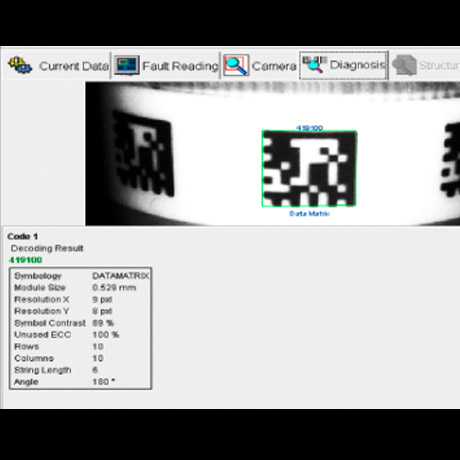

1D codes, 2D codes, QR codes, color rings and more – many industries use all kinds of codes to mark their products, make them easily identifiable, and collect data. The codes have to be read and checked back with a reference. In case there is anything wrong with the code, for example if it is not readable, printed in the wrong position or the code itself is incorrect, an error message is created.

Print Quality Inspection Systems

Packages contain a wide range of important information: from human readable (alphanumeric) expiration dates, serial numbers, and product names to machine-readable data like barcode or data matrix code. Hence print quality inspection is an essential part of the quality control in packaging in pharmaceutics, food, cosmetics, FMCG and many other industries. Based on given standards printed information have to be checked and verified.