Vision Inspection Applications

Advanced Vision Inspection Applications for Unmatched Quality and Compliance

In industries such as pharmaceuticals, food, cosmetics, beverages, and lubricants, maintaining consistent product quality and compliance is critical. Vision inspection technology plays a key role in identifying labeling issues, detecting faulty packaging, and ensuring regulatory conformity before products leave the production line.

At Laetus, we develop cutting-edge vision inspection applications that leverage high-resolution imaging, artificial intelligence, and automated analysis to help manufacturers maintain high production standards, minimize defects, and meet regulatory requirements. Our adaptable systems integrate effortlessly into existing production environments, helping businesses streamline operations, reduce errors, and ensure flawless product quality.

Vision Inspection – A Vital Component of Quality Assurance

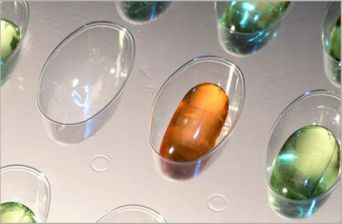

Vision inspection is an automated system that examines products and packaging using optical recognition technology, AI-based analysis, and high-speed processing. These solutions are designed to identify defective items, misprinted labels, incorrect serial codes, and damaged packaging before they reach distribution channels.

By integrating vision inspection technology, manufacturers can reduce human error, improve accuracy, and ensure consistent product quality. Advanced systems analyze products in real time, enhancing efficiency, regulatory compliance, and overall supply chain integrity. Industry regulations such as GMP, FDA, and EU directives require stringent quality checks, making vision inspection an essential tool in modern manufacturing.

How Laetus Vision Inspection Technology Optimizes Quality Control

Label and Packaging Accuracy – Prevent Mislabeled Products

Labeling errors can lead to misbranded products, compliance violations, and costly recalls. Laetus vision inspection solutions ensure that all barcodes, batch codes, and expiration dates are printed correctly, are fully legible, and meet industry specifications.

High-Precision Code Scanning – Assuring Data Integrity

To maintain accurate tracking and traceability, product codes such as QR codes, serial numbers, and barcodes must be completely error-free. Laetus vision inspection systems verify that all printed data is readable and compliant with regulatory standards.

Defect Identification – Detecting Imperfections Before Distribution

Physical damage, contaminants, and structural irregularities can affect product safety and brand reputation. Our AI-driven vision inspection solutions scan products at high speeds and immediately flag items with scratches, misaligned labels, or packaging defects.

Intelligent Process Monitoring – Real-Time Insights for Maximum Efficiency

Laetus vision inspection technology connects to ERP and MES platforms, providing live analytics and immediate error reporting. These insights enable manufacturers to increase efficiency, reduce waste, and maintain consistent product quality across production lines.

Industries That Rely on Vision Inspection for Quality Control

Pharmaceuticals – Meeting Strict Regulatory Standards

In the pharmaceutical sector, vision inspection is essential to verify that drug packaging, dosage information, and tracking codes are 100% accurate. Laetus solutions help manufacturers comply with GMP, FDA, and EU safety regulations and prevent counterfeit products from entering the market.

Food – Improving Labeling Accuracy and Safety

The food industry faces rigorous labeling and safety requirements. Vision inspection enables manufacturers to detect mislabeling, monitor expiration dates, and verify package integrity, reducing the risk of misinformation and recalls.

Cosmetics – Maintaining Flawless Packaging and Brand Consistency

Maintaining a high level of visual appeal and packaging integrity is essential for cosmetic products. Laetus vision inspection solutions detect labeling errors, incorrect packaging details, and branding inconsistencies to make sure each product meets luxury quality standards.

Beverages – Securing Packaging and Labeling Accuracy

From bottle caps to printed labels, the beverage industry requires precise packaging control. Our vision inspection technology ensures that logos, ingredient lists, and production details are accurately placed and legible, minimizing packaging errors.

Lubricants – Preventing Misinformation with Label Verification

Accurate labeling is essential in the lubricants industry, where product identification, hazard information, and batch numbers must be accurate. Laetus vision inspection solutions detect misprints, damaged labels, and incorrect barcodes, ensuring that products remain traceable and compliant.

Why Choose Laetus Vision Inspection Technology?

Laetus vision inspection solutions provide automated precision and real-time monitoring, to ensure quality production standards and regulatory compliance.

Our systems offer:

• AI-based quality assurance to detect misprints, defects, and packaging issues

• Regulatory compliance with industry safety and quality standards

• Automated processes that reduce reliance on manual inspection

• Improved product consistency by eliminating visual and structural inconsistencies

• Seamlessly integrate with ERP and MES platforms for real-time reporting

Raise Your Quality Standards with Laetus Vision Inspection Solutions

By implementing Laetus vision inspection technology allows manufacturers to detect defects early, maintain production accuracy, and avoid compliance risks. Our flexible, AI-driven systems provide real-time monitoring, intelligent defect detection, and complete process control to deliver unmatched product quality.

Contact our team today to find the perfect vision inspection solution for your business!

Product Identification