Blister Quality Control System

Blister control detects all kinds of defects regarding blisters and their contents. Therefore, the color, shape and dimensions of pills, ampules and other goods are checked as well as their position in the blisters. Wrong content as well as too much or too little content and faulty packaging is identified. This way producers make sure, that blisters are always filled in the desired way and only perfectly good products leave their production.

Well prepared for any eventuality

- Companies operating across many industries all around the world are constantly faced with countless challenges, from sourcing raw materials and driving efficiencies in production lines to complying with legal regulations and meeting guidelines. Strong competition in most markets means that it’s more crucial than ever to stay ahead of the game and exceed customer expectations wherever possible. And one of the best ways to do that is to sharpen up on quality control, making the most of the latest visual inspection technology to ensure that ingredients, final products, and even packaging are exactly as they should be.

Check, check and check again

- For the food, beverage and lubricant markets, as well as the highly regulated pharmaceutical industry, reliable fill inspection is a critical part of the quality control process. For example, checks on blister packs will typically involve identifying issues such as absent, partial or incorrect filling of the pocket, as well as damage or misalignment of the foils that are applied to contain the product. Picking up a consistent problem could highlight a fault in the manufacturing processes that would otherwise go unnoticed and lead to significant failure rates in production. On the flip side, if these defects slipped through, they would severely impact the quality of the final product and undermine customers’ trust if they were not spotted in time. But that’s not all.

So much to see

- Visual inspection technology also gives manufacturers the power to be able to extensively evaluate color, shape, exact dimensions, and even position of the product within the blister if necessary. Blister control can do all of this and more, detecting faults and imperfections along the production and packaging lines, and giving manufacturers the confidence that only perfect products leave their factories.

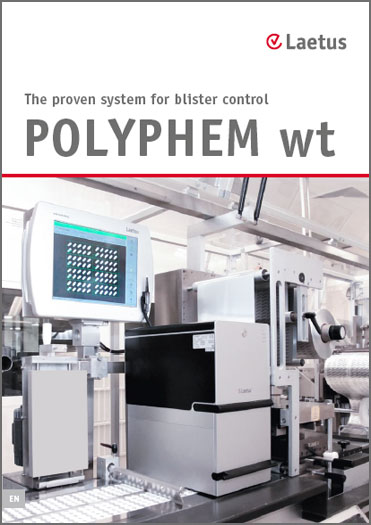

New dimensions to blister inspection

- Laetus has been collaborating very closely with companies around the world to offer a complete blister solution package that is tailored to meet their every need. Our perfectly designed, easy-to-integrate and intuitive systems are key to this, helping customers to maintain high-quality production for many years. For example, the POLYPHEM platform and MiraLux illumination unit cover all control functions and, together, efficiently detect errors in the filling process. These groundbreaking visual inspection solutions – which can be configured to individual company requirements – help to minimize unexpected costs, add value along the entire product lifecycle, and keep customers happy and confident in their processes.

Contact Us for More Information: