Print Quality Inspection Systems

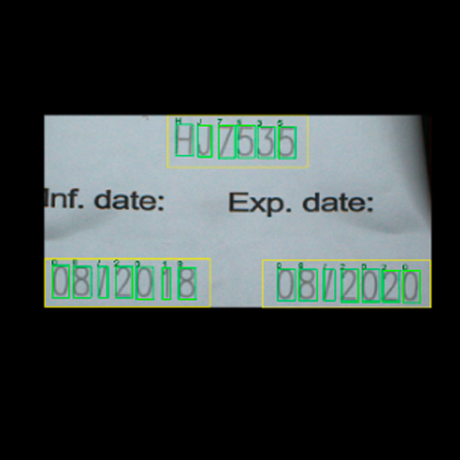

Packages contain a wide range of important information: from human readable (alphanumeric) expiration dates, serial numbers, and product names to machine-readable data like barcode or data matrix code. Hence print quality inspection is an essential part of the quality control in packaging in pharmaceutics, food, cosmetics, FMCG and many other industries. Based on given standards printed information have to be checked and verified.

It does what it says on the tin, or does it?

- The packaging for individual products displays a broad range of important information and artwork, from human readable alphanumeric – including expiration dates, serial numbers and product names – to machine-readable data, such as barcodes or data matrix codes. Much of this is essential to the end user as it confirms product authenticity and provides the key information that the customer needs to know, helping them to trust the brand and avoid any potential misuse or health issues.

Protecting your brand integrity

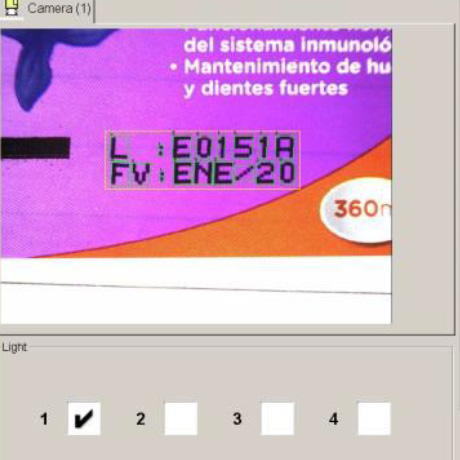

- For a manufacturing company, presenting codes on every branded good processed and distributed is crucial. It not only provides supply chain visibility and traceability to help flag counterfeits on the market, but it also tracks every transaction and minimizes costs and logistical headaches for unexpected recalls. Coding of products is perhaps the simplest and most efficient form of control, whether it’s a simple barcode, multi-colored Pharmacodes, a GS1 DataBar, a 2D data matrix or QR codes.

Perfect printing every time

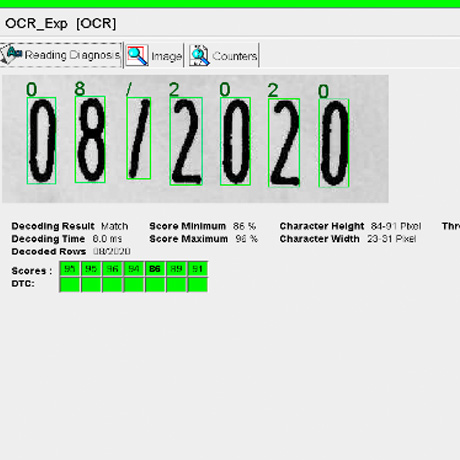

- Inspecting the print quality of codes and design elements – including logos and graphics – is an essential part of quality assurance for product packaging. Evaluations are based on given standards of criteria such as contrast, defects, readability, modularity and straightness. This is typically performed using a combination of optical character recognition (OCR) and verification (OCV) methods, which read characters, interpret fonts, decode, and compare information to a database to confirm if it’s correct. However, the increasing use of variable elements in addition to coding, means that there’s a growing need for more complex inspection and grading. Using more reliable and advanced technologies may be the way forward, especially in the beverage, food, lubricants and pharmaceutical industries.

Secure print inspection that goes beyond just code reading

- Laetus has worked very closely with customers around the world for many decades in order to fully understand these challenges, and has developed ideal solutions to meet the ever-changing needs of all sectors. Our remarkable ARGUS technology has been helping companies to check printing, and its new generation fulfills current quality and security requirements quickly and easily, with additional flexibility that is adaptable to future requirements too. Using a rotation tracker, ARGUS can evaluate any printing on labels, cartons and tubes at any desired position – even upside down – with unbeatable precision and speed for legibility and correctness. Ultimately, this impressive visual inspection solution helps to prevent counterfeiting of brands, and gives customers peace of mind that the packaged product offers exactly what it says on the label.

Contact Us for More Information: