Packaging Accuracy

Product packaging is the first thing that customers encounter and, as a result, it can be just as important as the quality of the product itself. Although its core purpose is to provide protection, accurate packaging should also ensure the correct distribution of goods from the warehouse to the point of sale, contain all the information relevant to the customer, and act as a marketing tool to boost brand awareness.

Eliminating costly packaging errors

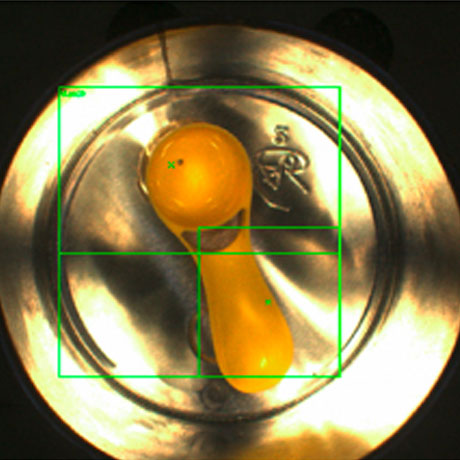

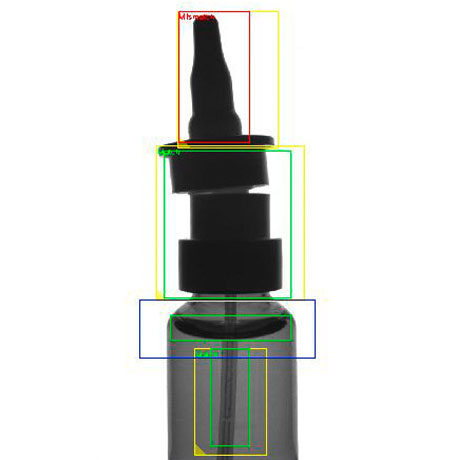

- In a busy manufacturing facility, multiple production orders are run each day for a variety of brands, and packaging each product correctly is becoming an increasingly complex task. Every aspect of packaging – from the robustness of the raw materials to the orientation, placement, precision, and quality of printed labels and barcodes – is essential to ensure a high quality overall product. Incorrect labelling of items or faulty packages can be extremely costly to manufacturers, resulting in product returns and recalls. At the same time, manual inspection of products and packaging is time consuming and costly, reducing production efficiency.

Maintaining trust

- As the primary touchpoint for many consumers, packaging can make or break a purchase, and poor quality packaging can significantly taint a brand’s reputation. Quality control systems are necessary to ensure that packaging is secure for safe shipping of products, and to check the accuracy of labels so that consumers have all the information they need about the product, its ingredients, and instructions for use. Minimizing all possible defects – including minuscule packaging fragments within the product itself – ensures customer safety and high standards that will strengthen a brand’s reputation.

Streamlining distribution and sales

- Packaged goods that leave the warehouse are at the mercy of the supply chain, and sometimes products are sold via unauthorized distribution channels or retailed at the wrong price. Re-routing of products on the grey market is not illegal, but it can significantly reduce company profit margins. Track and trace solutions like QR codes can be incorporated into product packaging to flag these issues. Similarly, accurate packaging of discounted goods can ensure that products sold as part of sales promotions are marketed at the correct price.

It’s what’s on the outside that counts

- Laetus serialization solutions assist companies across several industries to always reach the perfect level of traceability, offering insights into each stage of the product journey to ensure maximum control over brand image and sales. In addition, we have the software, hardware, and expertise to help manufacturers package their products for optimal product protection, supply chain distribution, marketing, and sales. Our vision inspection solutions are the perfect replacement for tedious manual checks, providing a cost-effective way to ensure that only the highest quality packaged products are distributed to customers.

Contact Us for More Information: