Packaging Execution System

Consistent batch production is essential during manufacturing to ensure that every item produced meets industry standards, serves its intended purpose, and satisfies customer demand. A packaging execution system removes human variability from the manufacturing process, ensuring reliable product quality, and enabling traceability of items as they enter the supply chain.

Consistency is key

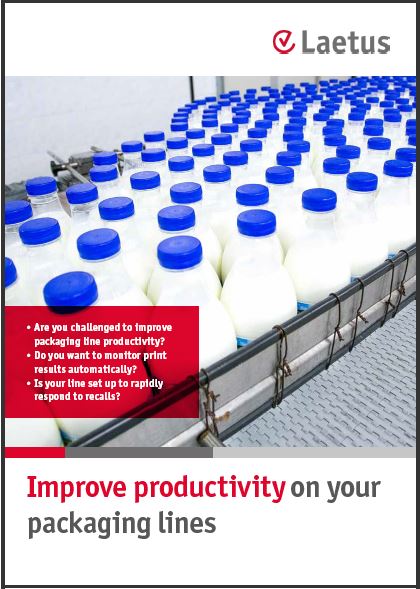

- The manufacturing landscape has undergone a massive transformation over the past 20 years, and factories are moving away from mass production to focus on generating smaller batches of customized products. Ensuring global accuracy is crucial during batch production, but discrepancies in packaging materials, product data availability, operator and shift team changes, and inadequate quality control measures can introduce variation into the manufacturing process. Having a strategy to avoid inconsistencies is essential to meet customer standards and reduce product recalls.

Quality over quantity

- Production monitoring is key to allowing manufacturers to track product and process standards in real time. However, more than 50% of all quality checks are currently performed through manual sample picking by operators on the factory floor. Manual inspections are time consuming and costly, reducing production efficiency and introducing the risk of human error into the quality control process. In turn, this can lead to imperfect products reaching the shelves, which can be hugely detrimental to a brand’s reputation.

Implementing serialization technologies

- Product serialization – assigning each manufactured item its own unique serial number – is becoming essential to meet customer expectations. Buyers are looking for products that match their personal values and attitudes to sustainability, and are seeking transparency in the items they purchase. Serialization is also beneficial to manufacturers, allowing them to monitor product quality and prove their social and health engagement credentials. Traceability ensures that faulty or unsafe products can quickly and easily be identified, but manual data entry poses the risk of human errors and inaccuracy. Instead, an efficient packaging execution system can monitor, track, document, and control the production process. This can ensure that all product batches passing through the line adhere to the same requirements, and that finished goods can easily be recalled if necessary.

Optimizing batch production

- Laetus works closely with customers to develop real-time traceability and quality control solutions that meet the ever-changing needs of manufacturers. Our serialization solutions help companies to support their consumer engagement strategies, improving product traceability and supply-chain efficiency. In addition, we offer the software, hardware, and expertise to detect any consistency issues in batch production. Our automated vision inspection solutions are the perfect replacement for tedious manual product checks, providing a cost-effective way to ensure that only the highest quality products are distributed to customers, while also increasing uptime to help companies achieve a return on investment in just 12 to 18 months.

Contact Us for More Information: