PHARMA-CODE Series: #3 PHARMA-CODE FAQs

PHARMA-CODE resembles a conventional barcode but the deeper you dig, the more different it reveals itself to be. Mistakes can be costly and not just financially. Here are the most frequently asked questions that we often receive about PHARMA-CODE.

A multi-color barcode?

Q: Why does PHARMA-CODE incorporate colors? Some colors are invisible to scanners and reflect differently when combined with black. This violates ISO and GS1 standards, right?

A: Yes it does, but PHARMA-CODE is only uses closed-loop applications. GS1 and ISO compliance is not applicable for this type of usage.

PHARMA-CODE must fit a very small space because of its purpose and the area of printing. There is insufficient space to make the barcode longer, so the color is added to enhance capability.

Q: What colors are permitted and how are they chosen?

A: Colors are entirely discretionary to the brand owner or packager. Color is less popular in PHARMA-CODE today than in previous years since today more types of the barcode were invented and applied by manufacturers. Now colors in PHARMA-CODE are mostly popular for marketing and branding purposes. But if it can be helpful to ensure correct packaging, color can still be used. Of course, color decisions must be compatible with packaging scanners.

A uni-directional barcode?

Q: PHARMA-CODE is not bi-directional. If you scan it from left-to-right, you get a different sequence of data than if you scan it right-to-left. How does the scanner know the correct sequence of encoded information?

A: The scanner cannot determine the correct sequence of the encoded data. There are no start/stop patterns, no human-readable, and no check digit. Remember, this is a closed-loop application. PHARMA-CODE does not utilize the safeguards and functionality built into open loop barcodes such as UPC and Code 128. The additional space these capabilities require is not available and—more to the point—the usage environment is tightly controlled.

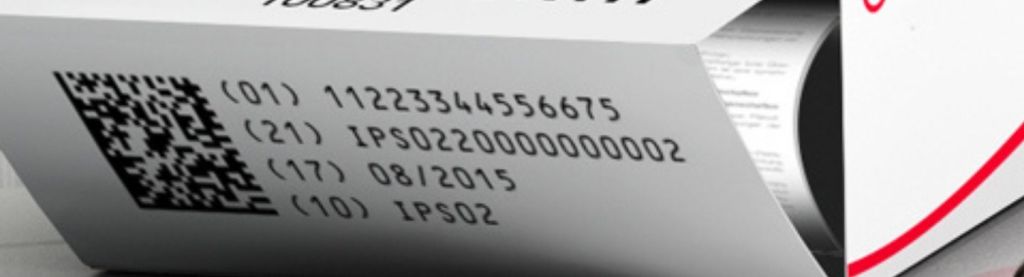

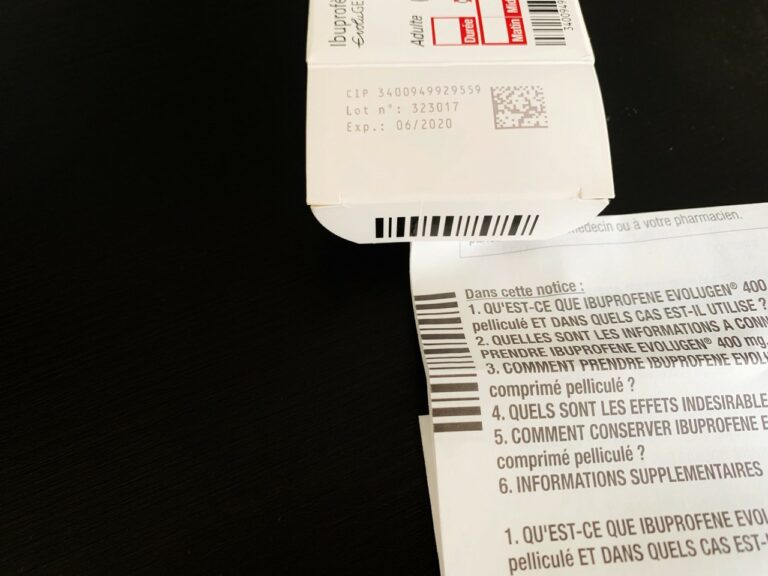

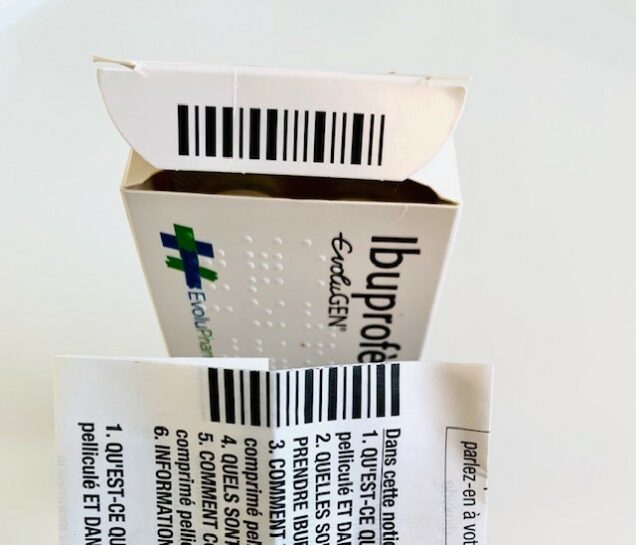

The orientation of PHARMA-CODE on the package and the inserts accords to design specifications. Installation of the scanners on the packaging lines complies with specifications. Everything works together in a specified, contained, and controlled system.

A barcode that ensures packaging accuracy?

Q: So how then does PHARMA-CODE ensure packaging accuracy?

A: PHARMA-CODE does a look-up to a manufacturing execution system, often called an MES database. This is a barcode match application. The barcode on the inside package flap must match the barcode on all of the inserts. When they do, the packaging operation proceeds. A mismatch triggers a system action, perhaps a full stop, maybe a shunt to a rework queue, a rejection into the reject-bin, or some other error quarantine.

*Co-authored with John Nachtrieb, CEO of Barcode Test.