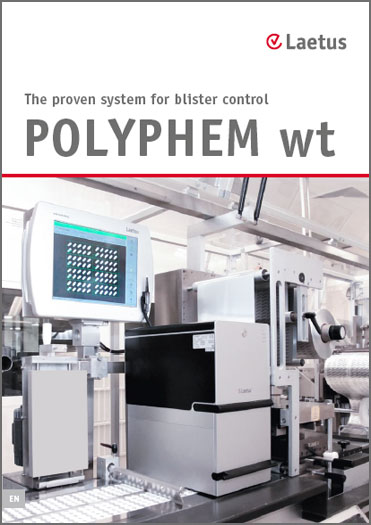

NEW: POLYPHEM wt9.0 Blister Inspection Solution

Effortless Quality Control with the new POLYPHEM wt9.0

POLYPHEM wt9.0 is the latest innovation in blister inspection designed to streamline pharmaceutical packaging quality control. Its fully automatic teach-in wizard makes setup fast and error-free, while the expanded evaluation range ensures reliable detection of even low-contrast products. With a user-friendly wide-screen interface and 30% faster parallel evaluation, POLYPHEM wt9.0 delivers rapid, accurate, and flexible quality control.

- All-in-one blister control

POLYPHEM wt checks the presence of colored tablets, dragees, and capsules and recognizes errors in form, color and position, as well as contamination, damage and overfilling.

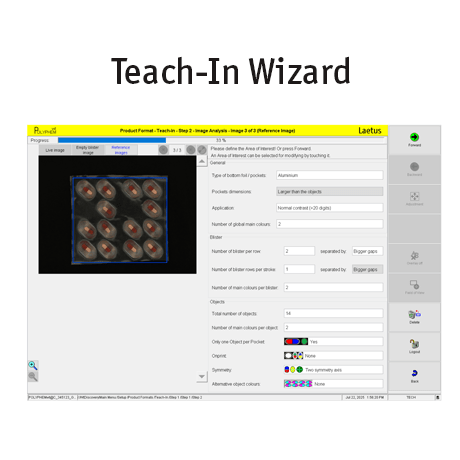

- Fully automatic Teach-In wizard

The POLYPHEM wt9.0’s teach-in wizard accelerates setup and minimizes human error by automating the training procedure, making it easy for users to configure the system for different blister formats.

- Expanded evaluation range

Detects a wide variety of low-contrast applications, including white-on-white and dark objects on aluminum foil, ensuring reliable inspection even in challenging scenarios.

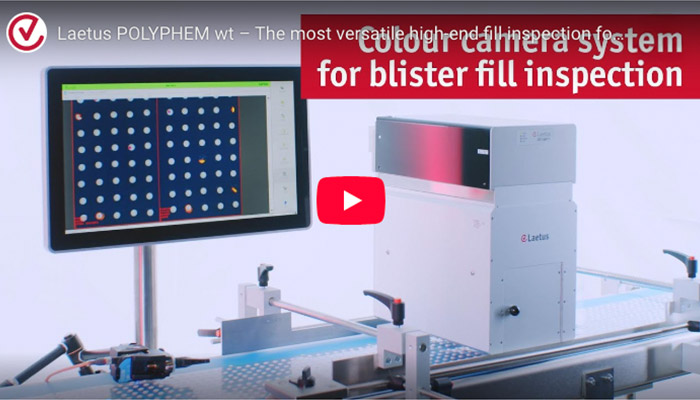

- Advanced GUI and mask layout

Features a new wide screen interface with optimized mask layout (image left, mask right), deviation bars, and intuitive controls for improved usability and faster error detection.

- 30% faster parallel evaluation

Utilizes parallel blister evaluation and dynamic blister tracking to deliver significantly faster processing and real-time defect detection

Applications

Increasing quality and safety requirements mean it is necessary to check for further criteria in addition to simply the presence inspection. Irregularities can occur when filling pharmaceuticals in blisters, which can have relevant impacts on the quality:

Presence

Lack of contents are unacceptable from a quality point of view and are immediately identified.

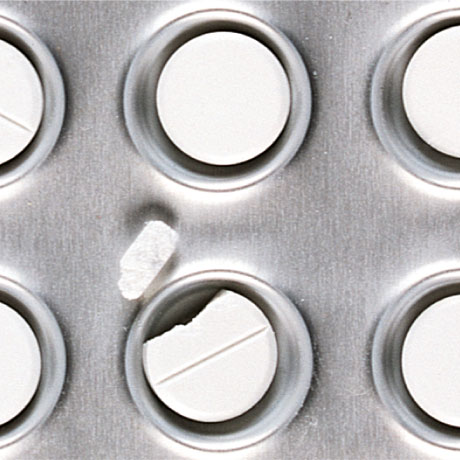

Damage/position error

Damaged products are ejected after clear identification. Objects outside of the blister are also identified. These must be removed before sealing.

Shape control

Shape control reliably detects deformed products.

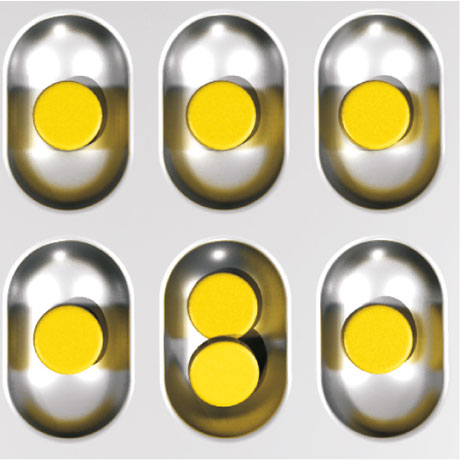

Overfilling

Double contents can lead to overdoses and must be removed from the process.

Soiling

Even the smallest amount of soiling is detected using the blister control or POLYPHEM.

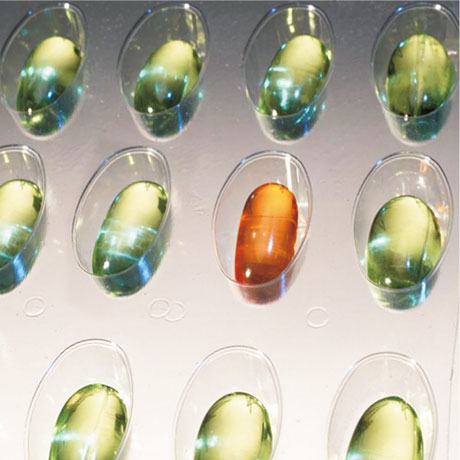

Foreign object/color mix-up

Unwanted mix-ups with foreign products are unacceptable for quality and product safety-related reasons.

Color

Incorrect colors are detected in monochrome products. The system detects each color or the combination for multi-colored products.

Orientation

This, for example, checks for products for which the orientation are a quality characteristic (e.g., bicolored capsules).

Measurement

The measurement detects whether, e.g., capsules have been compressed or are too long, which ultimately leads to damaged or incorrect fill quantities.

Contact Us for More Information: