Vision Inspection Solutions for Your Reliable Packaging Quality

Vision Inspection Solutions from Laetus provide inline, automated quality control to ensure reliable packaging quality at every stage of your production.

With intelligent camera systems and real-time image processing, you can detect labeling errors, verify codes, check sealing, and document every inspection step – fully automated and seamlessly integrated into your packaging line. This ensures that every packaged product meets the highest quality standards – consistently, efficiently, and in full compliance with industry regulations.

Looking for a vision inspection solution that fits your packaging process?

Discover how Laetus Vision Inspection can help you meet quality targets and reduce manual effort.

Why Vision Inspection Matters

Modern packaging demands more than speed – it requires accuracy, consistency, and traceability. Laetus Vision Inspection Solutions help you stay in control of your quality standards from the very first unit to the last.

Detect Quality Defects Early

Automatically identify printing errors, misaligned labels, faulty seals, or missing components – before they leave the line.

Ensure Compliance Across Industries

Meet international quality and labeling standards with reliable, documented inspection processes.

Reduce Manual Checks and Downtime

Avoid production stops, speed up line performance, and reduce operator workload with automated quality assurance.

Protect Brand and Consumer Trust

Deliver safe, compliant, and correctly labeled products – every time.

Inline Quality Control at a Glance

Ten critical inspection points ensure that every step of your packaging process meets the highest standards. From barcode verification and tube orientation to fill level and blister checks, Laetus Vision Inspection Solutions provide fully automated, real-time monitoring to detect errors early, reduce downtime, and maintain consistent product quality. This comprehensive approach supports a wide range of packaging types, including folding cartons, tubes, sachets, labels, bottles, and blister packs – ensuring reliable quality control across all formats.

10 Inspection Points That Ensure Your Packaging Quality

Identification using bar code / 2D code

Verification of printed barcodes or 2D codes for readability, correct placement, and product traceability.

Presence monitoring

Detection of essential packaging components such as leaflets, caps, or inserts to prevent incomplete deliveries.

Identification using color rings

Recognition of colored identification rings – particularly important for variant control in pharmaceutical applications.

Tube orientation

Ensures correct alignment of tubes for proper sealing, accurate labeling, and consistent presentation.

Presence and color inspection

Simultaneous verification of both the presence and correct color of elements like closures, labels, or product features.

Inspection of print quality

Assessment of the clarity and completeness of printed content including logos, graphics, and regulatory information.

Print inspection of plain text

Reading and validation of plain text fields (e.g. batch number, expiry date) using OCR to ensure accuracy.

Position control

Checks whether labels or printed elements are placed correctly – detects misalignment or skewed positioning.

Blister control

Inspection of blister packs to verify correct filling, shape, position, and completeness of tablets or capsules.

Fill level control

Measures product level in bottles or containers to ensure accurate dosing and avoid over- or underfilling.

How Do Vision Inspection Solutions Work?

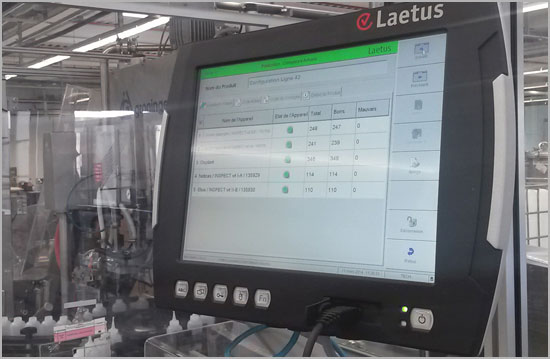

The intelligent camera systems are installed directly along the packaging line to inspect each product in real time. Depending on your production setup, they verify printed information such as batch numbers or barcodes, check label positions, measure fill levels, or detect missing components.

If a deviation is detected, the faulty unit is automatically rejected, and all relevant data is logged for audit and analysis. You benefit from seamless, fully automated quality control that is reliably documented at every step.

Vision Inspection Designed for Your Industry’s Quality Needs

Whether you’re in pharma, food, cosmetics, or another sector – our inspection systems adapt to your packaging processes and help you meet quality and compliance goals with confidence. Discover how we tailor our systems to meet the specific demands of your industry:

From serialization to blister inspection – robust, GMP-compliant solutions for pharmaceutical packaging.

Reliable detection of label accuracy, fill levels, and product completeness in high-speed food lines.

Ensuring flawless product presentation and traceability in premium cosmetic packaging.

Real-time fill level control, label verification, and bottle inspection for beverage manufacturers.

Accurate code reading and seal inspection in demanding production environments.

Looking for Concrete Application Examples?

Discover how our Vision Inspection Solutions are used in industries like pharma, food, and cosmetics to prevent errors and ensure quality compliance:

Find the Right Vision Inspection Solution for Your Packaging Line

-

PRINTER wt

Thermal transfer printer for direct integration into packaging lines, enabling high-quality inline printing of variable data.

Vision system for inspection of printed text and codes on labels, cartons, and foil packaging in track & trace applications.

Layout and code control system for checking printed data, presence, position, and plausibility – ideal for serialization and aggregation.

Compact all-in-one camera system for label and code verification with integrated illumination and processing unit.

-

POLYPHEM wt9.0

Inspection system for blister packaging – verifies shape, color, and completeness of filled cavities.

-

LLS wt580

High-speed linear line sensor for reliable barcode reading in fast-running packaging environments.

-

Inspector

Smart camera for quality control tasks – features compact design, integrated lighting, and flexible connectivity.

Efficient LED lighting module designed to ensure optimal image acquisition in vision inspection systems.

Industrial camera unit designed for use with Laetus vision systems – offering high-resolution image capture.

-

COCAM wt900

Compact code camera for reading 1D and 2D codes – even in confined spaces and high-speed environments.

High-speed color sensor for PHARMA-CODE™ and other color-based identifiers used in pharmaceutical packaging.

Looking to Improve Quality Control? Start Here.

Want a clear overview of how vision inspection can help your production line?

Our brochure shows you where it fits, how it adds value, and what benefits you can expect.

Why Choose Laetus?

Laetus is your trusted partner for vision inspection and inline quality control – offering reliable hardware, intuitive software, and ongoing support.

Extensive Industry Know-how

Decades of experience in regulated industries like pharma and food production.

Modular System Architecture

Easy integration into your line – scalable, upgradable, and compatible with your existing equipment.

Long-Term Commitment

From planning to validation, training, and technical support – we stay by your side.

Ready to Improve Your Quality Assurance?

Get in touch to discuss how Vision Inspection can safeguard your packaging process and help you meet your compliance goals.