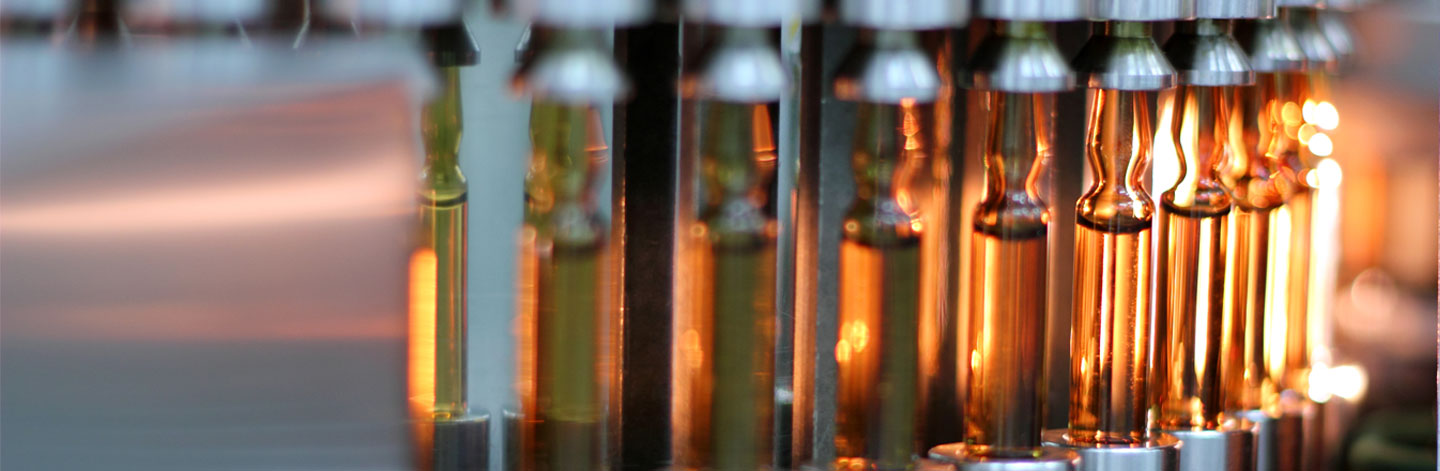

Vision Inspection Solutions

Image processing as the key to accurate vision inspection

The vision inspection of production and packaging processes is an important parameter of quality inspection and quality control in many areas of the production industry. Consistent product quality builds your customers’ trust in your product and, with low reject rates, guarantees highly efficient manufacturing processes.

Download brochure:

The world of quality control at a glance…

that’s what you’ll find in our new brochure. It shows a large selection of solution examples and product applications and provides an overview of the multitude of possible quality controls – with just one click.